My personal journey into home energy reduction began with taking stock of past energy use as reported on my utility bills. I quickly migrated toward reading the meters directly to gauge the impact of particular activities. What I learned from our gas meter shocked me, and ultimately led to our single-biggest energy-saving behavioral shift. I’ve already ruined any hope of suspense in the title of the post, but just how bad does something have to be before I’ll resort to a word like “evil?” And how bad are your own demons? Ah—now you can’t wait to find out!

Gas Gauges and Units

We must first confront the asinine measurement and units scheme of the natural gas delivery system. At least it’s asinine in the U.S. For one thing, the billing units are Therms. One Therm is 100,000 Btu, or 1.055×108 J, equating to 29.3 kWh. My main beef with the Therm is that the way my utility bill is formatted, my gas usage in Therms is printed within a few millimeters of my electricity usage in kWh. Since one may be directly converted to the other (both are units of energy), why not use kWh for both!? Not only is the kilowatt-hour already in common use in the U.S., it’s a metric measure shared by the rest of the world.

More importantly, putting gas usage in terms of kWh would immediately allow comparisons between energy usage from gas vs. electricity. As it is, there may be only a few dozen people in the country who habitually make the comparison. While we’re at it, we should demand that the utility bill report how much fossil fuel resource and how much CO2 is is associated with each expenditure. This becomes important in a side-by-side comparison because roughly three times the electrical energy delivered to your house is consumed in fossil fuel thermal energy, the bulk of which is waste heat. But this is another battle for another day.

The second misfortune about our measurement scheme is that we locked into cubic feet for the metering. I suppose we got lucky that electricity is measured in a metric unit—the kWh—so perhaps I am pushing it to whine about the use of an Imperial unit in the U.S. Sure, I’d prefer an internationally recognized unit, but a more significant gripe is that cubic feet is not itself an energy measure. Then again, oil is measured in barrels—even though the oil we use never touches a barrel—and coal is measured in tons that may have anywhere from 5000 to 8000 kWh/ton depending on the grade. At least the conversion between cubic feet and Therms is pretty easy: one hundred cubic feet (hcf) of gas contains 1.02 Therms of energy. I’ll forgive you if you just call it an even Therm (does my gas meter measure volume to 2% accuracy anyway?).

The third annoyance with the metering scheme is that the analog meters I have experienced have dials for which a full turn represents 0.5 cf, 2.0 cf, 1000 cf, 10,000 cf, and so on. Did you notice the gap? That gap makes it very difficult to do meaningful monitoring of home usage—which may be partly deliberate, I sometimes think. But we’ll push on and discuss how to use the meter for measuring pilot lights and their implications.

Measuring the Slow Burn

Below are two photos of my gas meter, taken exactly an hour apart, when no activities in the house demanded gas (water heater idle; no cooking; no home heating).

At lower left is the half-cubic-foot-per-turn dial, followed by the two cubic feet dial to its right. Both advance counter-clockwise. Over the course of one hour, the 2 cf dial advanced approximately two tick marks, indicating something like 0.4 cf in an hour. The ½ cf dial almost makes a full turn—perhaps 0.88 turns, corresponding to 0.44 cf/hr, in approximate agreement with the 2 cf dial. Naturally, the next-smallest dial, at 1000 cf per turn, does not budge discernibly. Without my telling you that the 2 cf dial has not made a full turn, there would be no way to know. Thus monitoring the gas meter requires vigilance and awareness of gas usage within the house. It’s easy to botch it.

At lower left is the half-cubic-foot-per-turn dial, followed by the two cubic feet dial to its right. Both advance counter-clockwise. Over the course of one hour, the 2 cf dial advanced approximately two tick marks, indicating something like 0.4 cf in an hour. The ½ cf dial almost makes a full turn—perhaps 0.88 turns, corresponding to 0.44 cf/hr, in approximate agreement with the 2 cf dial. Naturally, the next-smallest dial, at 1000 cf per turn, does not budge discernibly. Without my telling you that the 2 cf dial has not made a full turn, there would be no way to know. Thus monitoring the gas meter requires vigilance and awareness of gas usage within the house. It’s easy to botch it.

Converting the volume measure to energy units, we can express 0.44 cf/hr as 0.0045 Therms/hr, or 0.131 kWh/h, otherwise known as 0.131 kW (~130 W). Over a month, this racks up about 100 kWh of energy, which is no insignificant outlay.

The following table may help to navigate the various conversions involved in interpreting your gas dial. The first two entries are for complete turns of the two fine-scale dials. The last two entries are for turn rates; the final one expressed as how long it takes the ½ cf dial to make a turn at a usage rate of 10,000 Btu/hr. Many gas appliances in the U.S. (stoves, heaters, etc.) are rated in terms of Btu/hr, and 10,000 Btu/hr is a convenient baseline against which to scale appliance ratings. For instance, water heaters are often in the range of 30,000–40,000 Btu/hr, and home furnaces may be something like 80,000 Btu/hr. So for instance, a water heater at 30,000 Btu/hr would make the ½ cf dial turn once per minute.

| On Dial | Therms | Btu | Metric |

| 1 turn of ½ cf | 0.0051 | 510 | 0.15 kWh |

| 1 turn of 2 cf | 0.0204 | 2040 | 0.60 kWh |

| 1 cf/hr | 7.5 Th/mo | 1020 Btu/hr | 299 W |

| 184 sec/½cf | 0.1 Th/hr | 10,000 Btu/hr | 2930 W |

My First Encounter

In the spring of 2007, when I first gazed at the gas gauges, I was renting a condominium that used gas for only two things: hot water, and home heating. During a day when neither service was being utilized, I observed the 2 cf dial to be making 0.72 turns per hour, or 1.44 cf/hr. That adds up to 1050 cf/month, or 10.7 Therms per month (equivalent to 314 kWh/mo). At the time, I paid $1.30 per Therm, amounting to $14/month or about $170/yr just to run two pilot lights. That’s a lot of burritos, folks.

More distressing was the comparison to our annual gas demand, which averaged 28 Therms/month, dropping to 15 Therms/month during the summer months. Thus, our two pilot lights accounted for 40% of our total gas usage, and over 70% of our summertime gas usage! Outrageous!

Having uncovered this ugly truth, I promptly shut off the furnace pilot light, since we were unlikely to need heating any more that year. In doing so, I found its contribution to be 7.3 Therm/mo, or about $10/mo, and twice as large as that of the (remaining) hot water heater’s pilot. Shutting off my furnace pilot light therefore resulted in halving my summertime natural gas usage. That’s a big win. Not some few percent sliver, as is typical of efficiency improvements.

Pleased with our summer savings, we decided to hold off on re-lighting the pilot light the next fall until we simply could no longer tolerate the cold in the condo. That day never came. So discovering just how wasteful the furnace pilot light was unlocked a path to energy reduction on a large scale. How we cope without heat (in San Diego, granted) is a story for another time.

Over-eager Pilot Light

In my current house, as indicated in the photos and associated numbers above, the hot water heater’s pilot light consumes about 0.44 cf/hr, or 3.3 Therm/mo. This is pretty comparable to the old condo’s hot water heater, so is probably pretty typical.

This summer, I outfitted our hot water heater with thermochron iButtons to learn when the heater came on in order to get a sense for how much natural gas was being used to provide our hot water. I had one sensor on the cold water intake, one on the hot water output, and one on the flue chimney to sense when the unit fired up to heat a new batch of water.

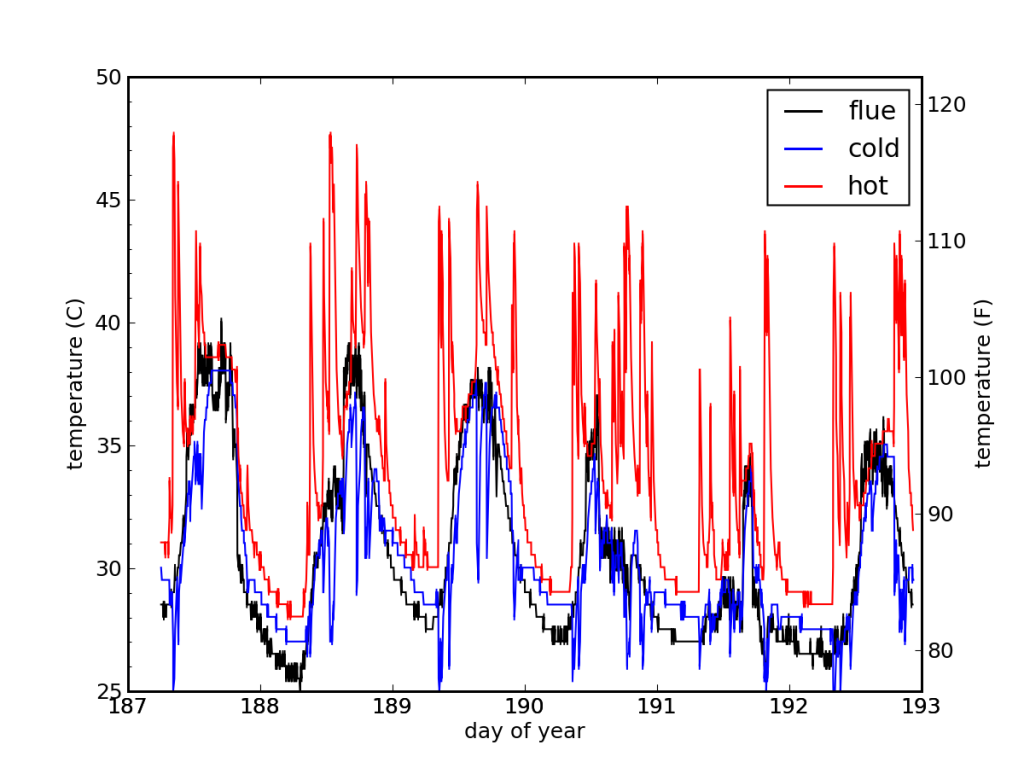

Over a six day period, what I found was that the heater never fired up! This is despite normal (albeit light) use of hot water for showers, washing dishes, etc. The plot below shows the measurements.

The flue temperature, in black, would have shot up off the plot if the heater had fired up. As it is, the flue temperature effectively provides a measurement of ambient temperature in our garage during this (hot) period. Hot water access is frequent, as seen by red spikes—accompanied by downward-going blue spikes as cool water is drawn into the unit. Based on measurements over a different period, the average temperature of the flue within the uninsulated, sun-beaten garage tends to be substantially hotter than the external temperature, by about 8°C (15°F).

The flue temperature, in black, would have shot up off the plot if the heater had fired up. As it is, the flue temperature effectively provides a measurement of ambient temperature in our garage during this (hot) period. Hot water access is frequent, as seen by red spikes—accompanied by downward-going blue spikes as cool water is drawn into the unit. Based on measurements over a different period, the average temperature of the flue within the uninsulated, sun-beaten garage tends to be substantially hotter than the external temperature, by about 8°C (15°F).

But the amazing thing is that the pilot light alone is providing enough heat to keep us in hot water during the summer months. How can this be true?

My wife and I are pretty sparing in our use of hot water: an average of five minutes per day at about 6 liters/min for showering (we’re each on a more-or-less two-day schedule), plus maybe a comparable amount for other uses. So let’s call it 60 liters per day (about 15 gallons). From the difference between the downward blue spikes and the upward red spikes in the figure, it looks like we’re heating water by 20°C during this period. Taking 4184 J to raise the temperature of one liter (kg) of water 1°C—in accordance with the definition of a kilocalorie—we require 5 MJ per day to heat our water.

From above, we see that my pilot light uses natural gas energy at a rate of 130 W. Over one day, this comes to about 11 MJ of energy. So we can easily accommodate our modest 5 MJ demand for hot water based on the steady expenditure from the pilot light. Of course there are losses due to heat escaping through the not-perfectly-insulated walls of the hot water tank and other paths. But we can use this investigation to conclude that such losses do not much exceed something like 50% given the 5 vs. 11 MJ matchup.

The Rub

So that’s kind-of cool that our hot water demand is below the level provided by the pilot light during summer. On the flip side, we lose regulation of the hot water temperature.

Normally, the hot water heater kicks on when the water temperature gets below the set-point. If the gas is never fired up, it means that our water never gets this cold. In fact, we find that our water is often too hot during summer. And it does no good if we turn down the thermostat: the pilot light conspires with the ambient temperature to determine the water temperature, and we have no way to turn the pilot light down.

So I would prefer a water heater with no pilot light (using electronic ignition like the seldom-used furnace in our new home), giving me control over the temperature set-point, and therefore how much gas we use. Or alternatively, a hot-on-demand system may similarly avoid wasted gas if it does not employ a pilot light. As it is, we are victims to our pilot light during the summer.

Of course other considerations keep me from rushing out to get a replacement water heater (embodied energy and expense to consider). Ideally, I’d like to move in the direction of solar hot water with natural gas backup. I am tempted to build the system myself—because it’s low-tech enough that I probably can, it would be cheaper to do it on my own, and I would learn a lot from the process.

Beyond Pilot Lights

Another profitable activity is to monitor the dials when a gas-consumer is on: furnace, hot water, stove, oven, etc. Not only can you confirm or discover the usage rate (often visible on a label in Btu/hr, for instance), but once calibrated you can use simple timing to tally gas usage. For example, if you know that it takes 20 seconds for the ½ cf dial to make a full turn when the furnace is on, and the furnace tends to stay on for 15 minutes at a time, then you know that each furnace cycle consumes 0.23 Therms, or about 7 kWh of energy.

What’s on Your Meter

I encourage you to check out your natural gas meter to learn how quickly you burn through gas 24/7 during quiescent times. I was truly surprised by what I found, and the behavioral changes fostered by this knowledge have had a tremendous impact on out home’s natural gas resource footprint.

Greater awareness of our resource usage (via measurement, metering, data) will collectively lead to smarter choices in the future. Many of our products are driven by consumer choice—informed to varying degrees. We need to educate ourselves and our friends on how to read, interpret, and act on the information available to us. If enough people were aware of pilot light pitfalls—as I have become—I imagine they would be more quickly phased out in favor of electronic ignition. Such a transformation is not without challenges (safety, failure, etc.), but it is not a stretch to imagine more widespread adoption of a technology that already has substantial penetration into peoples’ homes.

So when you are looking to replace a hot water heater or furnace, take the opportunity to kill the pilot light: and help rid the world of one more evil.

Views: 24650

That is a truly scary amount of energy being wasted. I wonder how many gas appliances in the US alone have similar wasteful pilot lights. I would imagine there would be tens of millions (or more) gas appliances with pilot lights. Anyone know a source for a concrete figure?

Furthermore I wonder how much of our annual usage of natural gas is wasted by pilot lights… It makes the 1-3 watt vampire drain of AC–> DC transformers seem like a drop in a bucket. Granted there are far more vampire electrical devices then gas appliances with a pilot light, but still.

You only looked at furnace and hot water heater, do you have any data for how many kWh a pilot light in a gas oven uses?

No. My current gas oven/stove has electronic ignition. But this is an opportunity: perhaps some DtM reader can put these techniques to work and report on other pilot light consumption rates. Best done if said pilot light is the only one being supported by the supply—else difficult to disentangle.

The UK switched billing of gas to kWh a few years ago for exactly the reason you give: easier comparison with electricity.

I regret that people use kWh though. Pedantically, hours are not SI units and megajoules would be a lot better. More practically, we’d also avoid all the confusion between kW and kWh, etc.

However, giving the volume (cubic feet or metres or whatever) first is sensible; it’s what the meter actually measures. The conversion from volume to energy is variable and is shown as a slightly different number on each month’s bill (at least here in the UK). I think it’s to do with changing average ambient atmospheric air pressure and the mix of the gas supplied.

In my old house I never turned off the pilot in the summer because I had heard of people having problems re-lighting them in the autumn – it was a very old boiler. In the house I’m currently renting I have LPG so don’t, unfortunately, have a meter to see what the pilot consumes. The gauge on the tank is far too imprecise to get an idea. Still, I turned it out last summer to save gas.

For comparison, US total energy use is 10,000 watts per capita, so maybe 25,000 Watts per average household. A couple of pilot lights (stove, water heater) is 260 Watts per household — 1%. It can be a big chunk of the household gas bill, especially for singles — hadn’t thought about it, but it’s probably most of mine; I get free heat and hot water, so I’m only paying for the stove, which is piloted, and actually I pay like the same amount every month, like my cooking doesn’t even register — but in aggregate, it’s not quite trivial.

While per-capita U.S. power is 10 kW, the actual expenditure in households is far short of this. Most of the per-capita power consumption happens outside the home. And for me personally, the pilot lights at the condo consumed 70% of my gas during summer. Not trivial at all.

In aggregate, 100 million households in the U.S. might have 10 or 20 GW of pilot lights!

We’re saying the same thing. It can be a big chunk of the household, but it’s tiny for the nation. Not like we can ignore the out-of-home consumption.

20 GW is funny, though. Could be the equivalent of 6-7 GW in electricity generation…

Though that 10-20GW of summer waste would go to zero more accurately be subsumed into the useful heating load n the winter, right?

My furnace pilot light’s heat is almost entirely vented to the outdoors, less the small amount that leaks out into my cold basement. It probably contributes very little useful heat in the winter — and certainly not in a useful place.

Some pilot lights are worse than others.

When we bought our current house, the furnace was about 30 years old, and had a very large pilot light on it.

We moved in during the summer, and as my family and I were fixing the place up, I noticed that one of the heat registers was fairly warm. I had assumed that somebody had just nudged the thermostat by accident, and we decided to just cut off the gas and power to the furnace, since we really didn’t need that pilot light running until heating season.

That fall, my Dad (an HVAC contractor) stopped in to give the furnace a check-over before we lit it for the season. Funny thing: we lit that pilot and it started with a roar! It was still fall, so we didn’t run the furnace that much, but that heat register in the living room was always warm.

The following summer, my Dad helped me again, this time tearing that furnace out and replacing it with a 91% efficient, glow-bar ignition, condensing furnace. The change in the gas bill was amazing.

Modern gas furnaces are great. I also had a 95% efficient condensing model installed to replace the 30 year old one in my house. Cut my peak heating month energy usage from 70 therms to to 20 therms. And the house was more comfortable!

I also measured the burn rate of the pilot light like Tom – not quite as accurately – but I measured a 8-10 therm reduction in monthly gas bills after shutting the furnace pilot off – very similar to Tom’s measurements.

The crazy part – my electricity bill was in the area of 400 kWh / month – so the furnace’s pilot wasted nearly as much energy as I used in electricity!

If you’ve got a furnace with a pilot – turn it off in the non-heating season!

I didn’t do the math, but I can say antidotally that the pilot for my fireplace was awful. I always felt warmth around the fireplace and one summer day it was to hot to just sit by and do nothing, so I felt it out and realized it was the pilot on my fancy “automatic fireplace – with remote control”. I turned off the pilot immediately – and was very proud of myself. I urge anyone reading to do the same. It was fairly easy to do.

I still don’t get why a house in Houston needs a fireplace… There’s probably thousands of homes in the Houston area that have these fireplaces with pilots going and are rarely ever used.

I just finished Crossing the Energy Divide by Ayres and Ayres, and they bring up two points salient to the discussion.

Because we don’t care about energy per se, but rather the services it provides (hot water, comfortable homes, mobility), what if utilities sold us energy services instead of natural gas or heating oil? They argue that such a shift would create an incentive to extract as much work as possible per unit energy and improve customer service (no more confusing bills). Even if this shift is impractical, it’s a unique way of thinking about how and why we use energy.

The second is that most water and space heaters are horribly inefficient if you use “2nd law” efficiencies instead of “1st law” ones. By “2nd law” they mean accounting for energy quality instead of just energy flow. (Hot bath water is less useful (in terms of ability to do work) than natural gas.) From that perspective, using high quality fuels such as natural gas or oil to heat a room is ridiculous! Better to generate electricity and then distribute the waste heat to nearby users. This is why they advocate that micro CHP be used in shopping centers, office parks, apartment complexes, etc.

Actually it’s not ridiculous, you can heat with natural gas at almost 100% efficiency. I don’t see how making electricity from gas at 30% efficiency and using the leftover waste heat for heating is any better. In fact one might consider it worse if there is enough electricity from solar and wind available.

Well, the trick is to burn the gas in a 50-60% efficient CCGT plant and then use an air source heat-pump with a COP of 2.5-4.5 depending on the unit and operating conditions. Now you’re getting 125%-250% efficiency out of your gas better than burning it directly for heat at ~97% for the best gas furnace – and bonus points if you can capture the waste heat from the CCGT plant for further use. And as the grid goes more and more renewable, your heat pump gets more efficient.

At least in California, with current record low gas prices, this is rarely economical with a therm of gas costing about $1.15 (4c / kWh equivalent) and electricity ranging from 14-30c / kWh depending on usage meaning that you need a COP of at least 3 to break even and potentially a lot more if heat pump usage puts you into top tiers paying 30c / kWh for electricity.

“More importantly, putting gas usage in terms of kWh would immediately allow comparisons between energy usage from gas vs. electricity. ”

Yes. That’s exactly why they don’t do it. Being able to compare things would only allow customers to make informed choices that would help them save money. And customers saving money means less profit.

This particular one is a very North American problem, both the units and the pilot lights 🙂

Here in metric land (Germany in particular) we have government mandated efficiency and emission standards for hot water heaters and furnaces, so most of those 30+ year old things have disappeared a while ago. Aside from that most city dwellers here live in apartment buildings where they have no control over how the heating system is managed, and nobody uses braindead things like gas fireplaces.

I totally agree with you. Here in the Netherlands they haven’t been outlawed yet, but I work as an energy efficiency advisor and have yet to encounter my first pilot light out in the wild. Practically every home here has central heating with a condensing boiler providing both heat and warm water.

Btw. here metering is done in m³ of “Groningen” gas. Which is the gas produced from the Slochteren field in Groningen. Conveniently that correspond almost exactly with 9kWh of HHV.

I still feel like going after personal consumption things like this is the wrong approach. Admittedly I’m surprised that pilot lights are so wasteful. But still, getting off fossil fuels is not something that’s going to happen on the individual level, because we’re not the heavy users- it’s the heavy industry and farming use that’s really the problem, and that’s not going to stop without organized political action.

One of the earlier articles here made the point that we should go after the really big, abundant sources of energy before we go after the little stuff. I’d suggest the same approach in trying to solve the problem- identify the biggest factors keeping us stuck on fossil fuel, and go after them first, before we start nagging everyone to be slightly more efficient in their personal consumption.

As a result of paying attention to my meters, I cut my domestic use by a factor of five (details in future posts). Call it little when you do it as well. If we all did similar things (and carried the awareness to the wider world) I think you’d no longer call it little. Don’t fear it!

Well that’s great, but you’re still just one person, and domestic energy use isn’t the main villain anyway. You’re still stuck living in a society that expects frequent air travel and heavy manufacturing, and even if everyone who has ever heard the term “peak oil” could make similiar savings that’s not going to change. We need organized political action, not individual consumer action.

Put it this way- to get our civilization off fossil fuels at the individual level requires convincing everyone on earth to voluntarily cut back, otherwise all the groups that don’t will just keep on exponentially growing their energy use. With political action, we only need to convince 50% +1 of all citizens.

Not to say that things like this are bad, of course. But I think their main use is as a political statement, and whatever savings they bring immediately are beside the point.

Gosh, if individual action is moot, we’re truly sunk. In some ways, I feel it’s the only thing we’ve got: it’s under our control, and it can have dramatic impacts if enacted by more than lonely me.

Politicians only follow popular sentiment. If people are not willing to cut back (and show with their actions that they are indeed willing), then how do you propose to get political action? Actions first, and words can follow, if they like. Take responsibility and control and show your peers the way. I’m tired of waiting for papa to tell me what to do.

I guess another way to say it is that politics does not bring about changes that people do not already want. When it comes to reduction, if you don’t want it enough to practice it as an individual, then there is no point in waiting for a political solution. We are the change we’ve been waiting for. Just do it. And other slogans as well.

If we abandon individual action as meaningful, how shall we hope to achieve anything through collective action – which starts at the individual level?

On a related subject, one person mentioned bath and shower water. My wife and I have found that you can recycle at least some of the water by using a basin and a smallish garbage bin to catch and scoop water. We use it when flushing the toilet. Sorry if this seems like TMI, but I think that every little helps when it comes to resource efficiency.

Individual activity is necessary, but what about “Tragedy of the commons”? The good people save energy and the bad people take a “free” ride.

That is the best and most convincing case for the “il faux cultive notre jardin” localitarian approach I have ever read.

It can’t save the “back to Norman Rockwell” version

http://kunstler.com/blog/2012/03/intermezzo.html

but it makes perfect sense if you don’t want to return to a past that never was. Well put.

“Never doubt that a small group of thoughtful, committed people can change the world. Indeed, it is the only thing that ever has.”

Personal use is a significant chunk. If you size it by GHG emissions (which dings the power companies extra for the coal that they burn), personal use (automobiles, in particular) is a good fraction.

Total fossil fuel CO2 emissions (2010) is 5.4Tg. 2.3Tg is electricity generation (including coal). 1.7Tg is transportation, .8 is industrial, .35 is residential, .23 is commercial. Of the transportation, almost 65% is personal vehicle use (.75Tg). Of the electricity, .64Tg is industrial, .84Tg is residential, and .77Tg is commercial. “Personal” fossil fuel use is the sum of the transportation and electricity shares, plus the “residential” component, or .75, .84, and .35, for a total of 1.94Tg, or 36% of the total.

Given the personal use is more than 1/3, we must be larger than at least one of two other competing FF consumers (farming use, heavy industry — though I’m working form CO2 emissions, not energy inputs, which dings coal for electricity production).

Tom,

I stayed for a while in an appartment in Seoul that had an on-demand hot water system for each unit in the building. Simply press the button on the console and you could have hot water for aprox. 10 minutes. What seemed really unusual was that the button on each console could only be activated 4 times in one day. Apparently this arrangement is not uncommon for newer buildings in Seoul. I think it is interesting that this arrangement is “normal” there but would probably be considered a type of rationing over here in N. America.

I agree with you that it doesn’t make sense to swap in a tankless heater in your situation for the reasons you stated (cost/embodied energy).

I also agree that installing a simple solar thermal system is a good idea (especially in your climate). Consider using flat-plate collectors as opposed to evacuated tube type collectors. Flat plate collectors are not quite as efficient at colder exterior temperatures but this disadvantage will hardly be relevant in your climate. Also, flat plate collectors are VERY simple devices that can last for many years with very little maintenance. A friend of mine has been using the same flat plate collectors for over 25 years with almost no change in their performance.

Given your line of work, I assume you posses a certain amount of mechanical aptitude and therefore I see no reason why you couldn’t DIY a solar thermal setup for domestic hot water. If you need to, practice your soldering technique ahead of time… and use MAPP gas and silver solder for the connections.

Tom,

Here are some solar thermal resources:

“Build it solar” is full of interesting reference material for all sorts of “home-scale” renewable energy projects – including solar thermal:

http://www.builditsolar.com/

A good review various solar thermal system options:

http://www.greenbuildingadvisor.com/blogs/dept/musings/solar-hot-water

Tom, I think I have to warn you against building your own water heating system:

This type of equipment can have non-intuitive and yet very deadly failure modes, so their design and construction is best left to specialised engineers and technicians.

Moreover, in most jurisdictions, any appliance connected with the natural gas supply, or with both the water supply and the mains, must be certified by appropriate authorities. Operating a home-made device, or a modified device, or even a certified device that was not installed by a licensed installer will be most likely illegal.

V,

I would agree with you if Tom was considering building his own steam engine. Solar thermal systems for domestic hot water heating are not that volatile.

However, if the tank is to use a gas back-up, I would recommend bringing in a professional to make the gas line connection.

It sounds to me like you just need to paint your current tank black, put some reflective surfaces around it on the floor and walls of your garage, and install a skylight directly overhead.

Maybe insulate the garage for those cold (50 F) San Diego winter nights!

A solar water heating system is pretty simple and low tech. I helped my father build one about 40 years ago, and he has built several others since.

Things to watch for:

– don’t solder pipes to the backing plate; differential thermal expansion will crack the joint. Just use a mechanical connection, maybe with some silicone thermal grease.

– watch out for galvanic badness

– have a plan for what to do if the temperature drops below freezing; can you drain your system? (if it runs water, which is easiest and cheapest).

– you can make a self-regulating system by putting the tank above the collector and arranging the pipes appropriately (my dad made one of these, it worked fabulously well), but this might not be a good idea in earthquake country.

– do you have a plan for overtemperature, if you are out of town for a while? (The self-regulating system above ran its whole tank of water up to some unholy temperature after a two-week vacation; we had to drain many gallons of extremely hot water.)

– I don’t know that glass is necessary for the face plate; I’m not good enough with the physics, but I got the impression that the primary benefit is reduced convection, not radiation, and acrylic or polycarbonate would also work well, and be somewhat more durable.

“…we decided to hold off on re-lighting the pilot light the next fall until we simply could no longer tolerate the cold in the condo. ”

We do this on many fronts and it makes conservation a fun game. One can view frugality as a hardship or an opportunity. People do better with some challenge in their lives. Imagine if one can get to a place mentally where hanging laundry is an enjoyable part of one’s day; two birds with one stone.

I think you’ll find the gap in the dials to be 100% deliberate — but not for the reason you think. As I recall from when I had natural gas, the supplier charged in units of 100 cubic feet, which corresponds exactly to the digits on the 1,000 cf dial.

But I’d guess calibration of the unit is required to be quite a bit more precise. That’s probably the reason the 0.5 and 2 cubic feet dials exist.

Dials in between wouldn’t exist because they’re not needed for calibration or billing, so why waste time and money on them?

Man, never realized what a big percentage that is!

My problem is I live in the mountains, hot air rising through the open beam ceiling, pilot lights in stove, heater and hot water and the realization that I still don’t know how to make enough money (usually another very energy intensive operation) to buy my way out. So we wear jackets, still have the heater on (way) more than I would like (or if I was by myself) and have to use a fan that makes it feel drafty.

Touching on Rich’s post, we used to keep the water in the tub because we didn’t want all that heat going down the drain. I figure the small amount of evaporation (in comparison to the whole of the bath water) doesn’t cause too much of an inefficiency to this “savings approach”, although it may cause mildew problems. Anyways, hot water CAN be better than the 60% lost or so to electricity.

Then again, we can’t let a baby to EVER get in the bathroom…

From there, I imagine if heat exchangers below the drain and “behind” the dryer being hard to justify.

Oh, I can actually feel the heat from the stove pilots even though they both look like they use about 1/5th of the water pilot (the heater uses even more). I know (in my case) it isn’t much, but shouldn’t these make the heater turn off by an almost equal amount?

about heat exchangers below the drain: According to an architect friend of mine, this is indeed be the next big chunk of energy that would need to be recovered to get substantial savings. With new homes in Germany all being better than 10kWh/m^2/year for space heating, the energy going down the drain in hot water becomes disproportionately large.

The conversion between ccf and therm is not that straight forward. First, pressure and temperature compensations need to be made between to metering for better accuracy and not all meters have these capabilities. Second, the conversion varies depending on gas quality and can range from 0.990 up to 1.035. The quality depends on the source and the actual components of the gas as natural gas is not purely methane. The conversion factor varies significantly with every sampling result.

Thanks for the added info. I can certainly tolerate a few percent variation, and should probably mix ignorance with convenience and start using 1.0 Therms per hcf instead of 1.02.

Tom, I’ve had a similar on-going love affair with my gas meter for many years now. Living in a cold climate, heating is my primary concern. I worked out a little routine to measure the heat loss of my house- it requires meter readings at the beginning and end of a roughly 24hour period. During that period, I take enough outside temperature readings to be able to calculate a pretty good average. It also requires that the house temperature be the constant throughout the period, so that there are no thermal mass effects. You can then calculate a figure that has terms of BTU’s/hr/deg, or whatever similar units you like. The result is surprisingly accurate and repeatable. I’ve been doing this for years, and tracking the decrease in heat loss with each improvement I make to my house. I’ve so far cut it by about 60%.

And thanks for the iButtons tip. I need some of those!

Next week’s post will strike some familiar chords for you, then. What range have you observed (in Btu/hr/deg or whatever units you want)?

Tom, the units I use are dekatherm/degF/day, (which seems like a totally bastard unit, but is what I had seen in print when I first started doing this, so I just went with it.) My house originally ran at about 0.013; now it’s 0.0053. I don’ have any illusions that this is good- I started off with a 100yo un-insulated house. One other point I forgot to mention – you need to do this test on an overcast day or the solar gain will totally skew the numbers.

Okay, thanks. If I put this in metric units, I get an old performance of 285 W/°C, improved to 115 W/°C. These numbers actually seem pretty good to me. My San Diego house is worse, in any case.

I used to keep my pilot lights off on my propane stove, and light it with a spent lighter when needed. But the concern was, was I releasing a lot more gas before ignition, and therefore, a lot of green house gas. Then the wife moved in and wouldn’t put up with the added trouble.

Where I’m living (Norway) electricity is very dominant for household heating, cooking and hot water (bear in mind we usually have an exess of hydropower nationally), but the going trend is to install more cables crossing the borders so there will only be a matter of time before we’re fully integrated in a (western) european powergrid. This will of course change the game considerably, with price rising and production source getting more dubious (and lessening a bit the dubiousness in the rest of Europe, I give you that). Time to look for alternatives, then.

I’ve tried to find the money to knock together an array of solar heaters combined with a water-mantled wood stove and a electric backup, problem is this also calls for radiators/floor heating circuits or some such device to get the heat into the rooms that need to be heated; for the time being this all amounts to too much work and cash when I’ve already got a functioning system. Here is a link to someone selling such a system- the principle seems to me to be quite easily reproduced. http://translate.google.no/translate?sl=no&tl=en&js=n&prev=_t&hl=no&ie=UTF-8&layout=2&eotf=1&u=http%3A%2F%2Fbye.no%2Fmain.aspx%3Fpage%3Ddocumentdetails%26doc%3DNyhet1&act=url

At those latitudes the only route to solar thermal heat, it seems to me, must involve seasonal storage – something to store those 20 hours of day of sun in the summer so that it can be used in the 4 hour a day winters. This has been done well enough to display 90% of the fuel for winter heating, but at a cost of $100K/home, so far.

http://www.dlsc.ca/how.htm

I store the summer energy in the form of ash, spruce, birch, aspen; hence the water mantled wood stove. That said, an solar collector array of 8 sq.m. will contribute if not fill even in winter.

Given that I currently run a farm with dairy cattle and forestry as the main incomes, and that we’ve recently shifted to producing firewood for sale instead of selling the lowgrade logs to paper production it seems logical to use some of the wares ourselves (as we currently do- but only for room heating, not hot water or food prepartion).

Contribute, yes. My point is I don’t see a path to *depending* on that solar collector in winter for those lacking Ash and Spruce acreage. At the highest US latitudes a flat plate angled at latitude might easily collect less than 2kWh/m^2/day for days in winter, so your suggested 8m^2 would collect as little as 16kWh/day, losing half at least, leaving 8kWh of heat per day to heat the house and bath water when it may be -20C outside. That won’t do even in a well insulated home.

These must have been very old gas furnaces/water heaters then. The only gas furnace with a pilot light I have ever seen was in a cheap flat I lived in for a year when I was a student (in 2003). The building was from 1961 and nothing had ever been renovated (yes, that’s why it was cheap!). I didn’t measure how much gas the pilot flame consumed then, but the casing of the furnace did get warm in summer just by the flame.

It seems that from the seventies onward furnaces with pilot flames dropped out of use, with older ones gradually being replaced. I’ve lived in quite a few buildings/flats over time since my student days and have never encountered a furnace with a pilot flame again. So I think the whole pilot flame thing is actually a non-issue, because very few furnaces with pilot flames are still in use (my guess would be <10%).

Also, in larger cities most apartment buildings constructed after around 1980 use communal heating, which is more efficient and less dependent on a specific fuel.

I should add that I’m describing the situation in central Europe, specifically in Germany, Austria and Switzerland, the countries I have lived in. It might be different in other parts of the world, especially in developing countries, I suppose.

I would like to say that space heating and cooling are the primary residential concerns… It seems solar heat could be stored for about what is spent on gas heating for a year… but nature has its way… Too many trees up here! Down in the desert (which is just 15 minutes away) it gets pretty cold still, but not frequent enough to justify all the gas heaters.

In the summer, it seems solar panels should be used directly for air conditioning (or better yet, swamp coolers), even though they are only like 15% efficient, as very little of that electricity has to go to waste.

I imagine more energy is consumed for cooling, rather than heating.

Wouldn’t it be nice to figure out how to “get everybody” to use a simple 12 volt solar system for the swamp cooler, the lights AND the computer/TV/sound system!

Actually with leds and the LiFePO4 battery, we can do the lights with just a 4v system (a single Cree XM-L will emit between 550 to 700 lumens at 3.2v and 2.1A, warm to cool white, respectively) But that entails making the panel yourself with a sandwich of 14 inch (non low iron) tempered glass and silicone… and most likely having to source out the batteries and the cells from ebay. 12v is nice because the panels are already made, just that you would have to use more leds or fancy electronics (not just a buck driver) but something that warns you when the battery gets low. With series leds, the forward voltage of the leds themselves (light dimming) prevents over serious over discharge.

Whoops, (I like solar lights!)

Ahh – more numbers than I measured. Our gas fired water heater was $80/yr to keep the tank warm and $15/yr heating actually “turning on”. Our low efficiency furnace put 1/4 of it’s total yearly gas into the pilot light. In the end I put in a 19 gallon electric water heater – the same cost per year (before time of use electricity pricing), slightly higher GHG emissions but we put it on a timer to only turn on for 90 minutes before the electric prices jump in the morning.

As a family of 4 our water use is 3 to 4 cubic meters per month; easily half that of our neighbours.

Note that on-demand water heaters are very expensive and in our case would simply not turn on for me when I shower (electric or gas). The primary benefit of on-demand heaters, over a properly sized well insulated electric tank, is their greater efficiency. Newer gas fired tank water heaters have a smaller pilot and some are electric ignition, but about the same amount of energy as the pilot is required to keep the tank warm. The ones with the flu up the middle (“B” vent) are, of course, sucking conditioned air out of the home all the time and that’s an energy cost. “Power vent” ones solve that problem but require an electrical feed for the combustion air fan – and I’ve not power metered one of them yet.

Keep in mind 1/3 of our GHG’s, or energy use, is food, 1/3 our home and 1/3 our vehicle. The food is the one to go after first. It’s a pity that fuel efficient cars can not be had for love or money. Our early 90’s 52hp Chevy Sprint was excellent and by now I’d have expected much better milage, sub 1L engines – but the cars are generally all much more powerful, make more GHGs and only some hybrids are better in stop-and-go city driving. Low-E glass is cheap and easy to put into vinyl window frames to cut heat gain in the summer and loss in the winter. Induction cookers are 30% more efficient than electric and 2x as efficient as microwave ovens – but you’ll never recoup your purchase price. One will never consume their way to sustainability.

Recently I discovered that radiant floor heating is nearly evil. Keeping a slab at >40C and having minimal insulation under it means that in the homes I’ve seen, around 1/5 of the total heating energy goes into the ground. Homes which have that sort of heating typically have a HRV and I’ve seen those improperly sized without home owner instruction and poor controls for operation, dumping about another 1/5 of the total winter heat produced right outside and plunging home humidity into desert conditions (in the north).

I don’t know the relative prices, but calafonts, on-demand hot water taps (I think usually gas powered) are common in Chile, a country with $10-15K per capita income.

“Keep in mind 1/3 of our GHG’s, or energy use, is food, 1/3 our home and 1/3 our vehicle. ”

I question that, unless you’re counting agricultural methane as GHG, which is valid but distinct from energy use. The simple breakdown I’m used to is 1/3 electricity, 1/3 heating, 1/3 transportation. http://cdn.physorg.com/newman/gfx/news/hires/2011/usenergyuse.jpg is more detailed, though doesn’t call out food.

For exaclty the reasons you identifed, 3 years ago I converted my gas hot water tank to electric on a timer. This reduced my water heating bill from about $250/year to about $75. Subsequent super-insulation of the tank reduced the annual bill further to about $50/year. Conversion was not difficult and the new system has been working flawlessly for the past 3 years, but it’s by no means “to code”. If interested, see my project and analysis at http://www.IWillTry.org.

Also, super-insulating an electric tank is much less expensive and just as effective as electric on-demand with a preheating tank. Electric on-demand systems are simply not scalable; if everyone used them, peak electrical demand would skyrocket. Super-insulation, by comparison, allows operaton of an exsting hot water tank on a timer which can significantly reduce peak electrical demand.

Love your blog. -Rob

Neat stuff on your site Rob!

Yes we added extra insulation to our 19 gallon electric tank and that cut the standby power draw from 30W to 22W (stock R8 + 1.5″ fiberglass). I then tried to make a jacket of 2″ ISO foam but that didn’t help at all.

I also added a U heat trap and although there was a temperature difference of the exit pipe (indicating lower heat loss) there was no measurable reduction of energy use.

Lastly – if possible reducing the length of water pipes is critical. When I shower I have to purge around 1.5L of cold water from the pipes before I get the 5L of water I use to shower. Reducing the diameter of the hot pipe and shorter pipes (local on-demand water heater?) would be of benefit. I’ve seen it all done wrong on a “green” home. They use a radial piping (one water pipe to every endpoint device – the modern paradigm to reduce pressure drops but increase the amount of piping and energy loss due to purging cold water to get hot) but not before they put the heater on the first floor, then piped it down to the first floor and distributed it from there. They #@$ ran hot pipes thru a concrete slab and running five (instead of 2) 1/2″ pipes into a bathroom means that the drain pipe had to be supersized.

My favorite insane solution to having to purge cold water was seeing a home built so that it constantly circulated hot water thru the [uninsulated] pipes – only costing around $700/yr!

What actually is the point in a pilot light? I assume it’s to ignite the main burner in a boiler but why can’t it just use an electric spark like a gas stove?

A pilot light is just a simple way to ignite the burner. A standing pilot (on all of the time) is the default as it allows a device such as a water heater to work without any electrical power. A work around for this on some tankless heaters is to use a spinning turbine in the pipe to detect that water is being used and to provide energy to ignite the gas. Yes some mfgs. noticed that the pilot light uses a signif amount of fuel.

Note that in newer tank gas water heaters the pilot light is much smaller. It’s a trade-off in terms of how low you can go and yet not have it snuff out.

In a typical water heater the pilot light also keeps the tank warm – the main burner only turning on when a signif. amount of hot water is removed.

The other main issue with a standing pilot is that the combustion gases must be vented – so a vent pipe up thru the middle of the tank (totally uninsulated of course) constantly sucks conditioned air out of the home – that’s why insulating (add extra) a gas tank water heater is pointless.

The “solution” to that is a water heater which has electric ignition, requires electricity, and also has a combustion fan and a vane to shut off the airflow thru the water heater. They’re no more efficient, use electricity, still require the same amount of gas to keep the tank warm but they stop conditioned air from being sucked out of the home.

Nice work here. I’m not too excited by your rant that the meter reports exactly what it’s measuring: you’re obviously capable of forming your own interpretations, and as others say, assumptions about conversions matter at least a bit.

As somebody who has a gas water heater and all other gas appliances are electronically ignited, I plan to do my own investigations. Thanks for the link to the sensors. I had thought of a small computer embedded in water heaters, one that’d only fire up in anticipation of our ordinary schedule, and they’d be the link.

Assuming, that is, that our pilot isn’t ALSO the primary way that we heat our water. I wonder whether your heater is an old enough model that the pilot burns thru more gas than current models; it’d be interesting to see how that matters. (Appreciate any info you have about that via a direct email.)

This doesn’t surprise me one bit…. My Mother in Law has an instantaneous gas water heater, the original one that came with the house had a pilot light. Her gas comes in 45kg bottles (what the hell’s a cubic foot..??) making it very difficult to monitor; as the price of LPG started soaring, it became evident to her back pocket that her heater was worn out. After years of nagging from me (the eco Nazi!) she finally replaced it with a 5 star Rinnai piezo electric start device……. and her gas consumption HALVED!

Now I’m her hero…..!

I used to have an old-fashioned boiler with a pilot light and a header tank. Yes, it cost more money in fuel, but it never went wrong. Now I have an efficient condensing boiler and pressurised system, with no pilot light or header tank. But the thing goes wrong from time to time and is full of technological wizardry your standard plumber has no chance, I have to pay top notch to get highly trained people to fix it. It’s cost me far more in having it fixed than any amount of gas I might have saved.